Enamel, also known as vitreous enamel or porcelain enamel, is a borosilicate glass layer that can be applied in liquid or powder form and can fuse onto a metal surface such as mild steel, cast iron, stainless steel, aluminum, or similar metals.

What is Enamel Coating?

This inorganic coating has been used since around 1000 BCE by the Egyptians for art and jewelry and can be characterized by a range of unique chemical and mechanical properties such as:

- Color stability (over many years)

- Corrosion resistance (even against boiling water!)

- Easy to clean

- High temperature resistance

- Scratch resistance

Typical Applications:

Enamel has been embraced by many different industries worldwide for a wide range of products to provide functional and/or decorative coating. Enamel coating prices vary depending on the process performed.

- Architectural panels

- Bathtubs/shower trays

- Barbecues (grills)

- Boilers/water heaters/hot water tanks

- Chemical tanks/reactors

- Stoves/cookers

- Heat exchange panels and tubes

- Homeware stores/kitchenware

- Microwave ovens

- Street signs

- Valves

- Washing machines

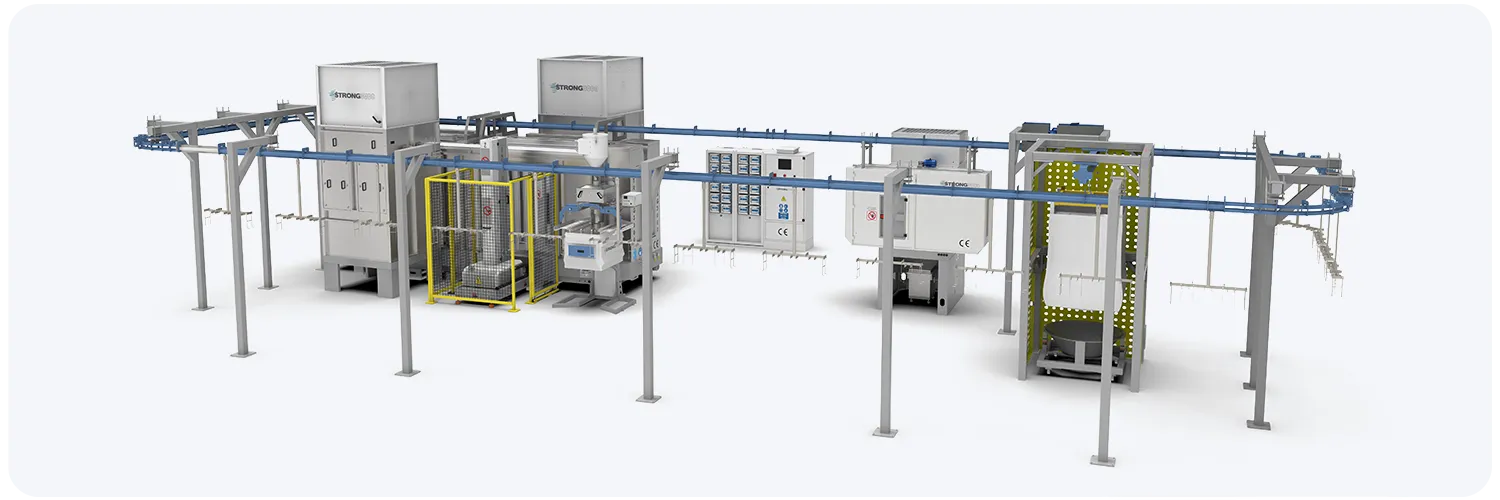

How is Enamel Made?

Especially heat-resistant kitchenware is coated with enamel frit. Companies that perform enamel coating produce and sell enamel frit, glass frit, aluminum frit, inorganic pigments, ceramic coating solutions. The enamel raw material is prepared in powder or liquid form by mixing and spraying with oxides of elements such as sodium, lithium, potassium, barium, calcium, zinc, and magnesium depending on the place and properties of use, aluminum oxide, phosphorus pentoxide, and fluoride borosilicate glass. This new coating material, called enamel coating, is useful. Enamel pot repair can be done.