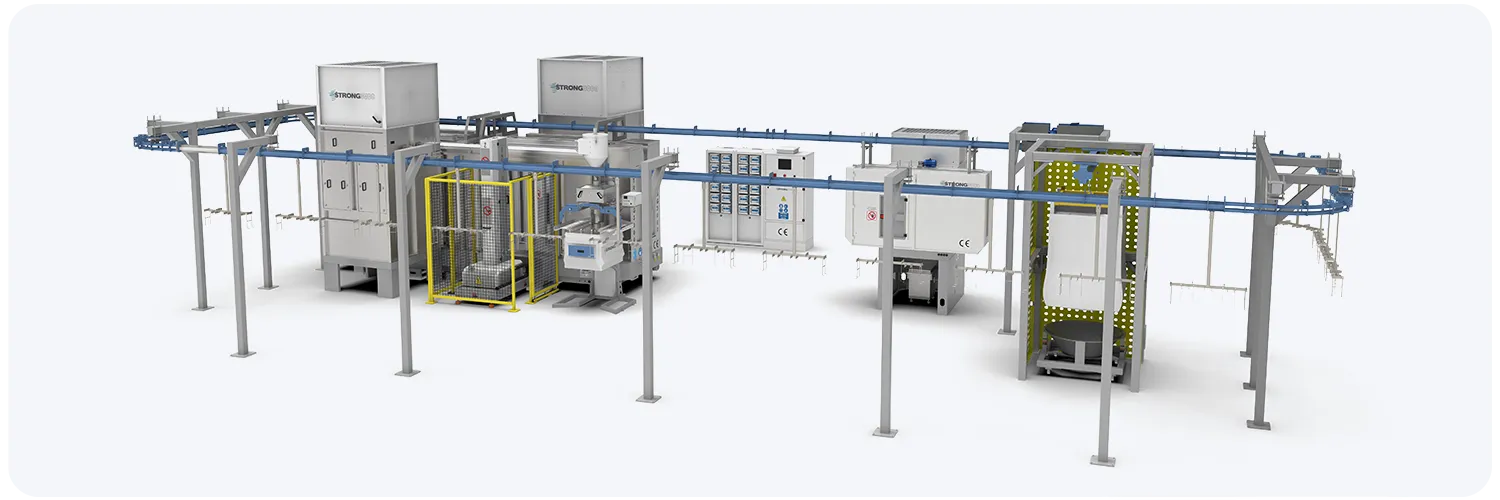

Wet Enamel

Wet Enamelling Booth provides high performance in your industrial painting processes with its special design and durable structure. High quality enamel coating ensures long life and durability of the booth, while offering operational flexibility and easy cleaning advantages. By choosing this booth, manage your processes reliably and efficiently, and optimise your processes.

Wet Enamel Vacuum Cleaner System

It is a special solution that makes your processes more efficient and environmentally friendly. Integrated into the tanks located underneath the Wet Enamelling Booth, this system efficiently transports the used wet enamel accumulated on the booth floor. This process minimises waste and makes your operations more sustainable. The Wet Enamelling Sweeper System minimises environmental impacts and offers a sustainable production practice while increasing efficiency in your facility.

Zero Leakage Maximum Wet Enamel Absorbency Zero Wet Enamel Loss

Thanks to the Wet Paint Enamel Filters, 100% recycle and use the wet enamel entering the system.

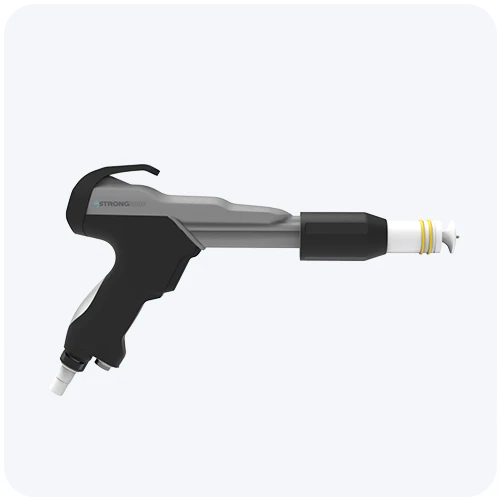

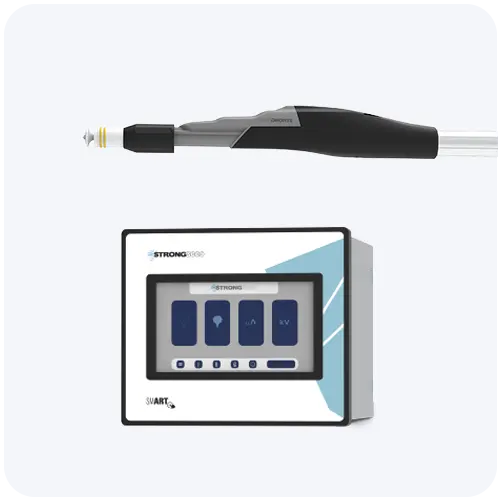

Paint by Rotating Your Parts

Put your workpieces on the rotating apparatus and paint them thanks to the rotating apparatus. Contact us for your different workpieces

Wet Enamel Warehouses

Wet Enamelling Tanks are used to recover the wet enamels accumulated in the tanks, filter unit and cabin atmosphere fed by the sweeper system located in the plant. This integrated system is designed in accordance with the principles of waste minimisation and sustainable production. The wet enamel in the tanks is effectively recovered within the system, thus making production processes more environmentally friendly and economical. This feature allows you to manage your plant in an environmentally friendly way, minimising wet enamel waste.