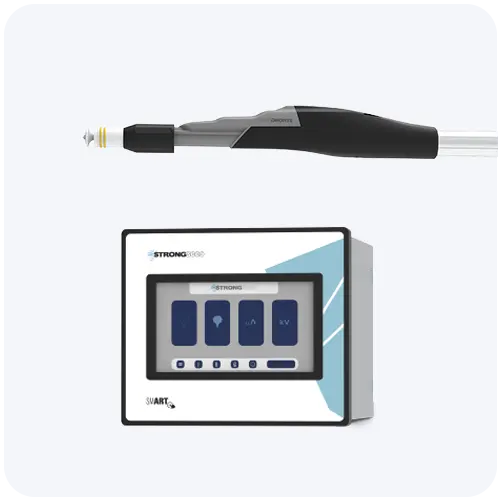

Smart Powder Coating Device

Smart Device optimizes production processes with touch control and integration with Industry 4.0. It offers advantages such as the ability to remember 100 different parameters, Wi-Fi connectivity, and remote access. Powered by a 32-bit Cortex 18 ARM microprocessor running at 600 MHz, this device provides an effective experience with 128 RAM and a 7-inch TFT touchscreen. This is a significant step towards making future production more efficient and sustainable.

Smart Device: Pioneer of Industry 4.0

Touch Control

The Smart Device optimises production processes with touch control and Industry 4.0 integration.

High Capacity

It offers advantages such as the ability to remember 100 different parameters, Wi-Fi connection and remote access.

Processor Power

Powered by a 32-bit Cortex 18 ARM microprocessor and 600 Mhz processor speed, this device has 128 RAM.

Remote Access

You can manage your device with remote control and you can also examine all active status.

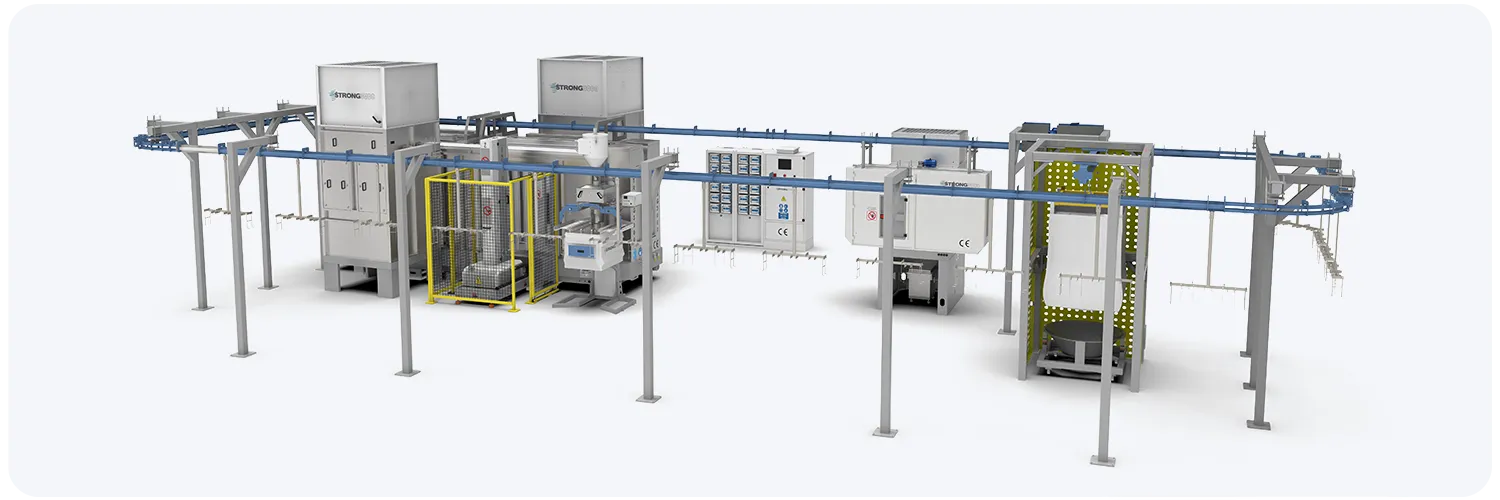

Harmony of Precision

and Performance

The injector of our powder coating device, which allows you to achieve perfect results from fine details to large surfaces, combines superior performance and precision. With its innovative design and durability, it is a reliable partner for you in your most challenging painting jobs. Always your best choice for professional results.

One Touch!

The injector of our powder coating device, which allows you to achieve perfect results from fine details to large surfaces, combines superior performance and precision. With its innovative design and durability, it is a reliable partner for you in your most challenging painting jobs. Always your best choice for professional results.

Current and Voltage Technology (Scv)

The current and voltage feature (SCV) works by automatically adjusting the current and voltage to provide stable maximum adhesion to the material with minimum paint.

This technology creates negative ions by disrupting the neutral state of the air through the high voltage applied to the needle by the cascade in the powder spray gun. These ions adhere to the powder particles and this process is called “Corona system”. Our guns also work with this loading system. However, in order for the paint to adhere homogenously to the material, the material must be completely grounded.

Remote Access

It provides remote access thanks to its Wi-Fi feature. This feature allows users to access and control their devices from anywhere.

Furthermore, users can remotely adjust important parameters such as kV and µA. In this way, the production process can be more precisely controlled and optimised.

Smart powder coating machines aim to increase the competitiveness of enterprises based on technological innovations and industry 4.0 principles.

Smart Air Control Valve

The Smart Air Control Valve provides early warnings via the Smart Control Panel when compressor pressures are unstable. When compressor limits are approached that could inhibit powder ejection, the device is automatically optimised and when a critical level is reached, the device is stopped to minimise errors and product losses.

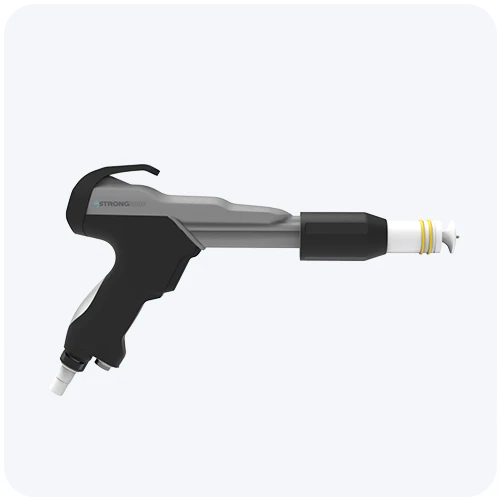

EXPROF TRIGGER STRUCTURE

Durable and silent trigger structure

numerous manual pulse power.

EASY DISASSEMBLY HEAD STRUCTURE

45 degree rotation in one go

install and remove the head nut and head assembly.

DISASSEMBLE AND ASSEMBLE HOSE HOLDER

Latch type hose holder

Easy disassembly and assembly with the apparatus.