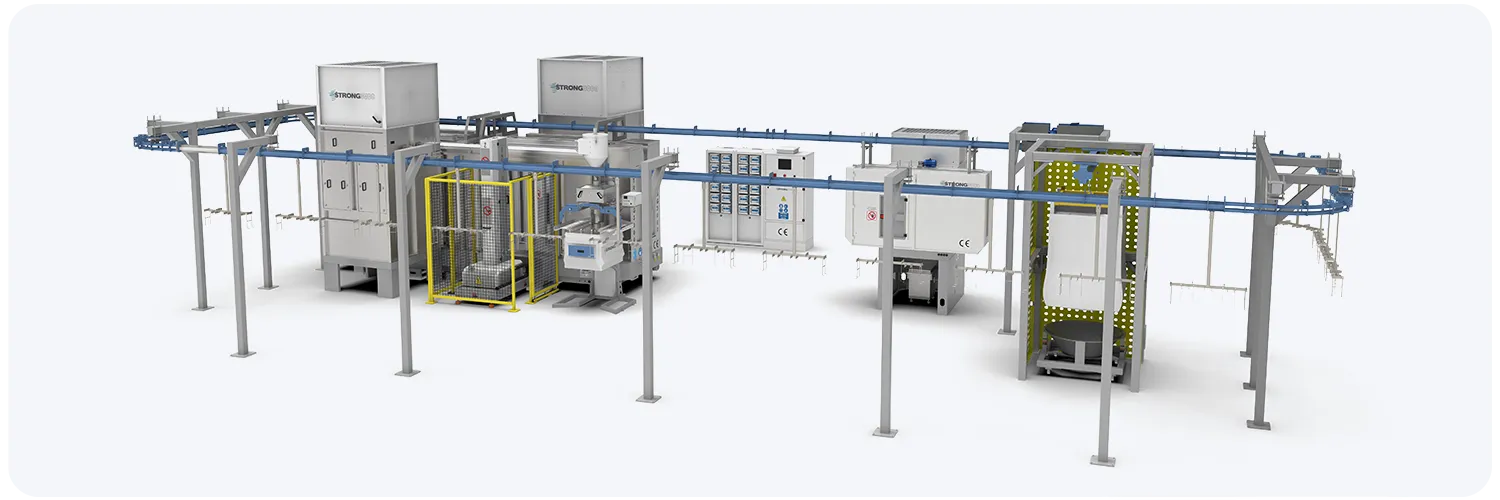

Powder Enamel Equipment offers significant opportunities to industrial sectors with advancing technology. Faster, more precise, and higher-capacity production and processing tasks become achievable. The next-generation enamel equipment with advanced technology allows harnessing the advantages brought by powder coating systems. It enables capturing the high resistance capacity crucial in industrial applications. Being longer-lasting, aesthetically appealing, and cost-effective makes it the preferred choice for companies today. The Strong3000 device, with its high-capacity application efficiency, effectively applies this dynamic to every point, hence widely used today.

Powder Enamel Equipment

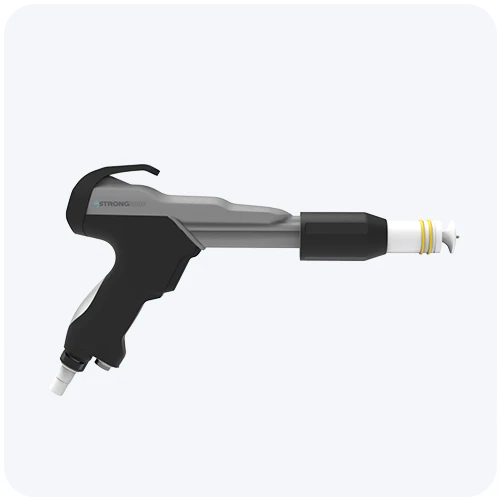

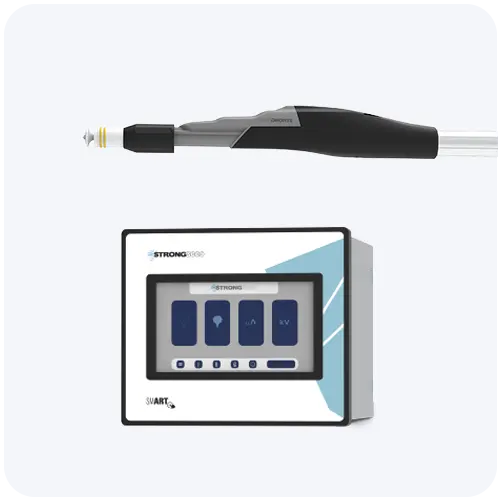

Among the Powder Enamel Equipment, the widely used Strong3000 system is developed with a comprehensive structure. Thus, it can dynamically respond to every need in facilities. With its high reliability and adjustable current and power capacity, it can perform surface and product-oriented tasks. Therefore, it allows for a more precise powder coating application in every field. Its high compatibility with different gun systems also helps in reducing costs. Its compatibility with all widely used powder enamel equipment eliminates additional needs, thereby contributing significantly to cost or investment reduction.

Powder Enamel

Powder Enamel Equipment enables surpassing boundaries in the industrial sector and finding solutions to unique demands and needs. The system prioritizes quality and safety, creating healthy and safe working conditions. It includes painting machines, robot systems, recycling systems, painting, and enamel systems. Particularly, powder system alternatives for enamel systems receive intense interest. Nowadays, it covers various areas such as boilers, stove pipes, and white goods enamel. Thus, it accommodates special functions for different usage areas and needs. Due to the extensive application sector, special systems are used for enamel coating. Alongside powder enamel coatings, there is a product portfolio including wet enamel system and baking system.