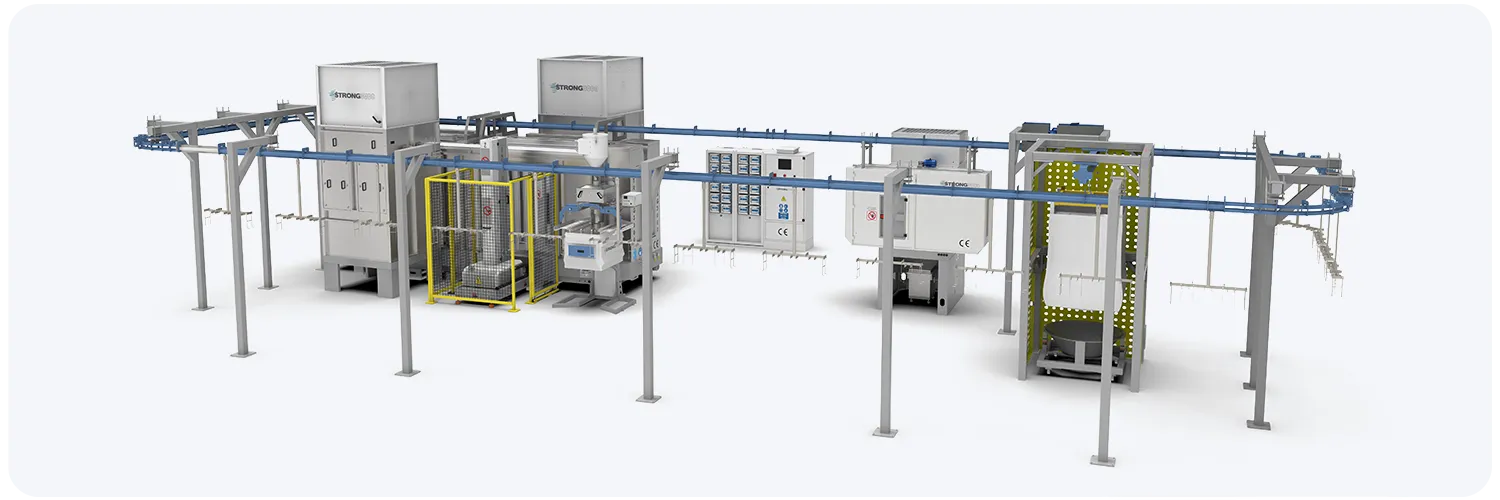

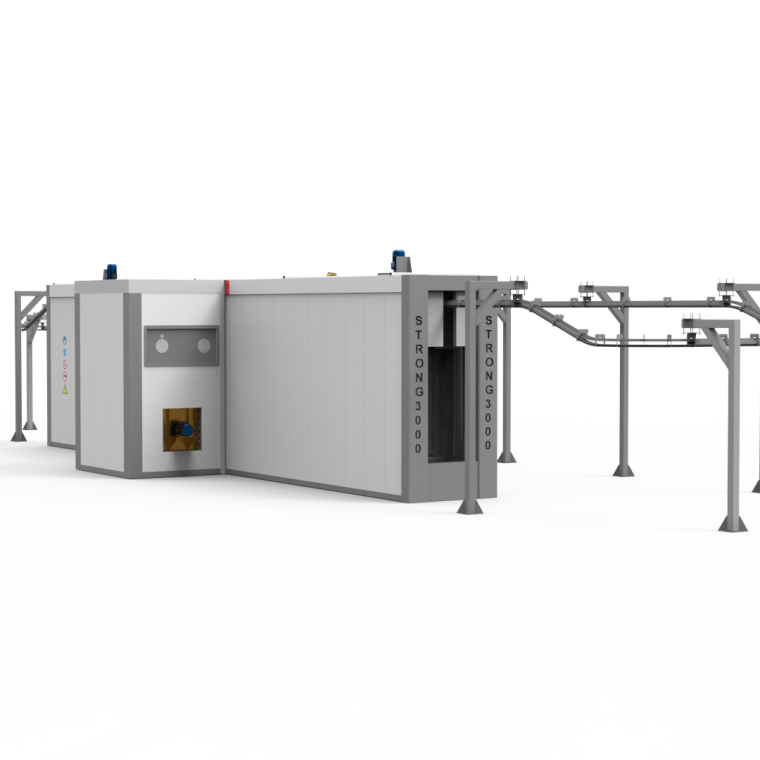

Toz Boya Kabinleri (Powder Coating Booths), enable painting processes to be carried out more precisely and healthily today. Especially ensuring that intensive chemical interventions, such as the painting process, are performed under healthier conditions. Thanks to the powder coating booth, painting on products prepared for painting can be carried out more precisely. With the compatible Strong3000 powder coating device, more precise painting can be applied to the product surface. The products prepared for painting and passing through the powder coating booth move on to the second stage in the painting system. The painting process is completed with powder coating ovens. The question of how to do second-hand powder coating arises out of curiosity, aiming to reduce costs in the industry.

Published in:

Blog E

Powder Coating Booths

7 months ago

Next-Generation Technology in Powder Enameling: STRONG3000 Smart Coating Systems

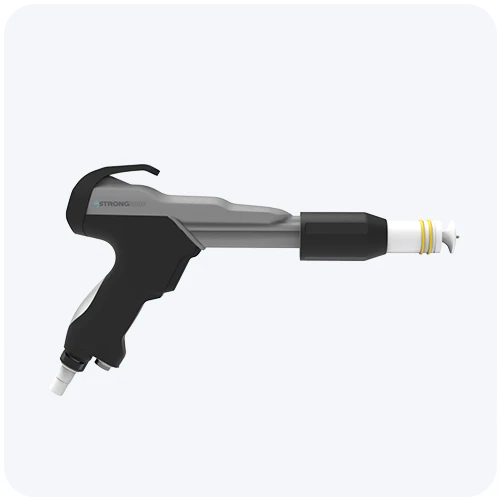

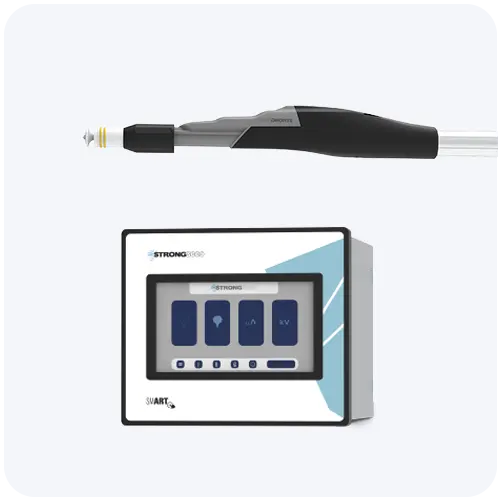

STRONG3000 offers next-generation solutions in powder enamel coating systems. From smart powder enamel devices and TP2 powder coating transfer pumps to stainless steel booths, cartridge filter units, and ultrasonic recovery systems, all components are engineered for durability, efficiency, and seamless integration through advanced automation technologies.