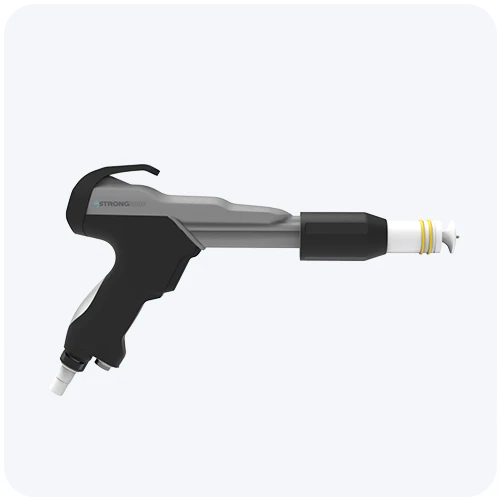

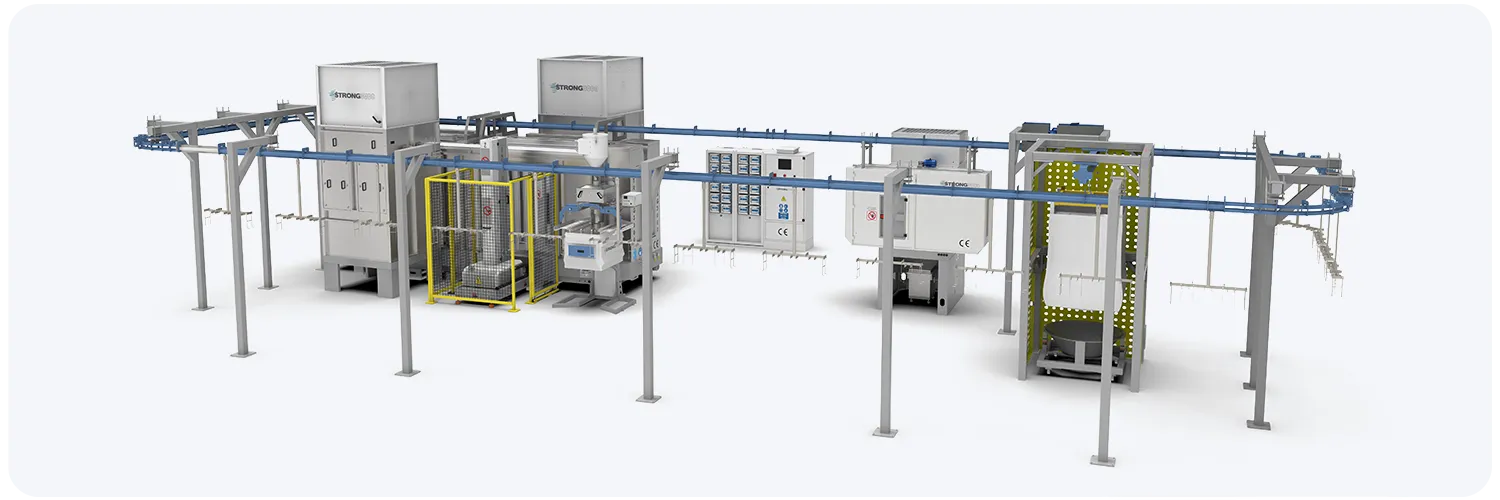

Powder coating booths enable painting processes to be carried out more precisely and healthily in today’s standards. They particularly ensure that painting processes, which involve intensive chemical interventions, are conducted in healthier conditions. With a powder coating booth, the painting of products prepared for painting is performed more precisely. With the Strong3000 powder coating device compatible with the product structure, more delicate painting can be applied to the product surface. Products prepared for painting and passing through the powder coating booth proceed to the second stage in the painting system. The painting process can be completed with powder coating ovens. The question of how second-hand powder coating is done arises in the industry with the aim of reducing costs.

Powder Coating Booths

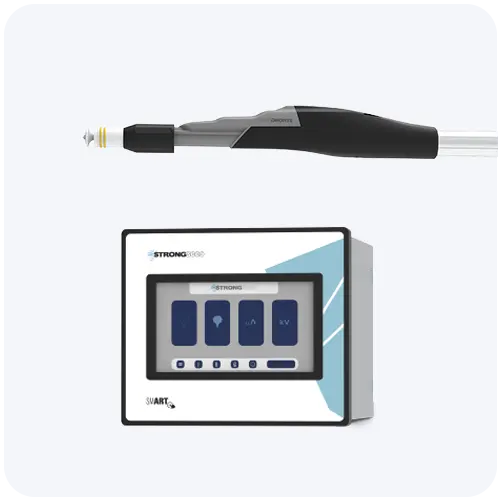

The quality of powder coating booths and powder coating device directly determines the quality and application capacity of the processes carried out. With Electron powder coating products, it is possible to achieve this quality and serial application. This is because the static structure allows the paint to be applied to any surface most quickly. It offers a wide range of products in terms of powder coating equipment with its highly advanced infrastructure and expertise. In this way, it is possible for companies to meet all their needs in powder coating systems from a single point at affordable prices. Powder coating facility in Izmir provides quality and professional solutions for companies’ powder coating needs.

Powder Coating

Powder coating booths and electrostatic powder coating systems aim to minimize companies’ costs. Especially for industrial-grade devices and products, fuel or energy requirements can be very high. This can significantly increase costs. In order to reduce this, fuel or energy costs in products such as electrostatic powder coating devices are reduced by 30%. In this way, it is possible to reduce general production and application costs. This provides an important advantage to companies in the manufacturing sectors in today’s Turkey. It also contributes to increasing the quality and capacity of production nationwide. Thus, it provides significant support for the development of industrial sectors and directs development. Therefore, it is widely and intensively preferred today.